CUSTOMER - Water Authority of Fiji (WAF)

LOCATION - Waiwai, Ba, Fiji

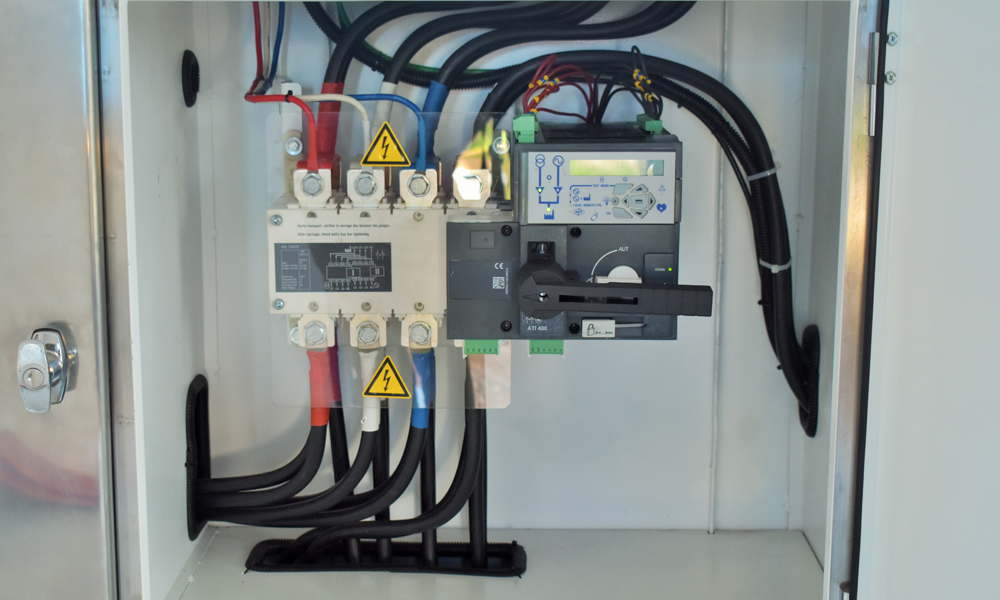

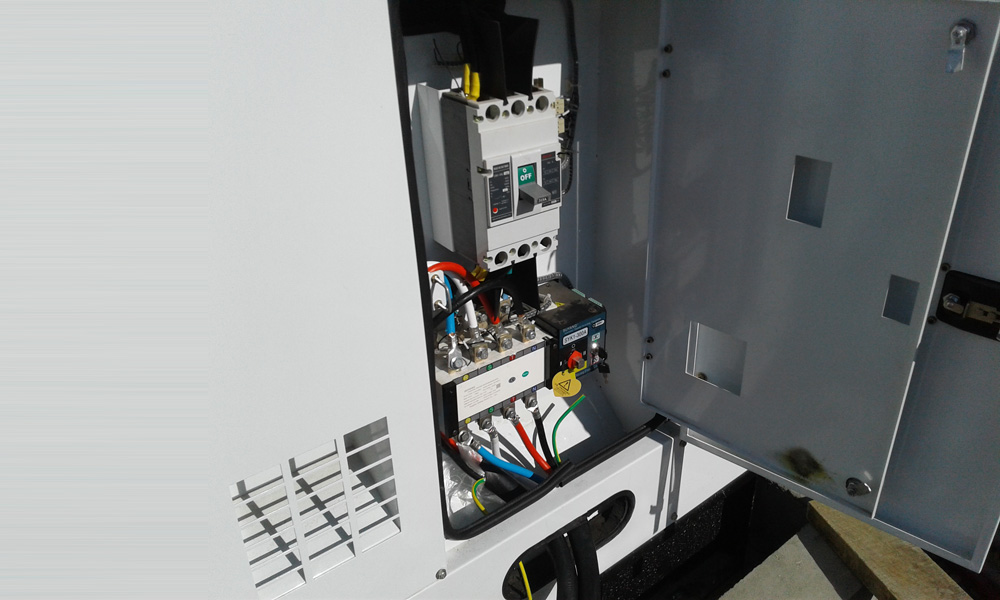

SCOPE - The work included the design, supply and installation of all the electrical power and lighting works for the WTP. The specific tasks include:

The installation was such that a standby generator power supply could be retrofitted. Our customer was pleased with our efforts and had this to say “Thanks for the good Job done in Waiewai”. This job was completed months ahead of schedule so the people of Ba could enjoy the benefits of WAF’s new investment in the WTP.

The WTP was inaugurated by the Prime Minister of Fiji.

CUSTOMER - Water Authority of Fiji (WAF)

LOCATION - Savusavu, Fiji

SCOPE - The work included the design, supply and installation of all the electrical power and lighting works for the WTP. The specific tasks include:

The installation was such that a standby generator power supply could be retrofitted. Our customer was pleased with our efforts and had this to say “Thanks for the good Job done in Savusavu”. This job was completed months ahead of schedule so the people of Savusavu could enjoy the benefits of WAF’s new investment in the WTP.

The WTP was inaugurated by the Prime Minister of Fiji.

CUSTOMER - Mobil Oil Mariana Islands, Inc

LOCATION - Saipan, Commonwealth of Northern Mariana Islands (CNMI)

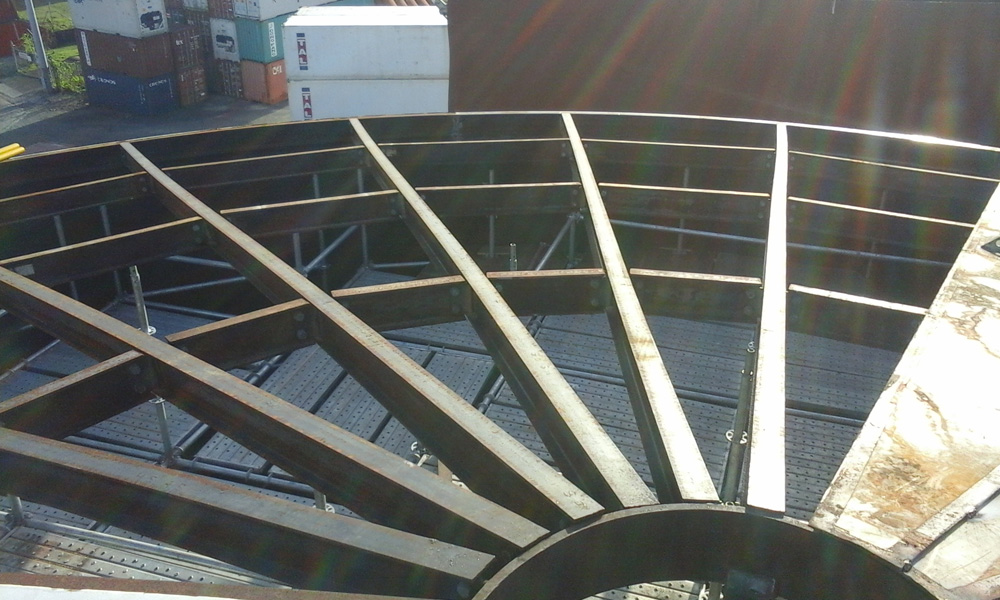

SCOPE - This project was a design and construction of a bulk fuel storage tank (swing tank which would be able to store all products available at the terminal). PEP designed the tank to API650 and ExxonMobil standards including independent certification by a US Professional Engineer (PEng) and CNMI registered structural engineer.

PEP supplied the pre fabricated tank kit set, onsite fabrication, installation and testing of the tank. The scope also included the blasting and painting works, hydrotesting and installation of nozzles and associated piping. Tank capacity 4500m3.

CUSTOMER - Palau Public Utilities Corporation (PPUC)

LOCATION - Malakal, Koror, Palau

SCOPE - This was complete design, build and operations management project. PEP contributed significant value engineering for the customer on this project right from the tender stage. We offered an alternative to the process requested by the client. Our alternative sequence batch reactor (SBR) process was accepted. Later our use of a belt press instead of sludge drying beds was also accepted.

The specific scope included several tasks including:

The plant is designed for unattended operations. We are also responsible for management of operations and maintenance over a five-year period.

CUSTOMER - Water Authority of Fiji (WAF)

LOCATION - Kinoya, Suva Fiji

SCOPE - The scope was the refurbishment and conversion of the existing defunct SBR into an unattended IDEA plant. This included the demolition of existing infrastructure, concrete repairs to the SBR basins, installation of 6 x 90kW blowers, all stainless steel air piping, ultra fine bubble membrane diffusers, upgrade of electrical switch room building, design supply and installation of new main switchboard, PLC and SCADA controls and buildings to house the new blowers.

The hydraulic system was upgrade with large diameter underground concrete pipes, construction of new concrete water retaining structures (to act as distribution chambers), supply and installation of weirs and the design supply and installation of isolation penstocks.

The digester was refurbished with external coating and new relief valves. Handrails were replaced with aluminium handrails throughout the plant. All deteriorated concrete surfaces were refurbished with specialised coatings throughout the plant.

New inlet step screens were designed, supplied, installed and commissioned. The three trickling filters had all the filter media replaced with new media and the mechanical distribution systems replaced with stainless steel mechanisms. The primary sedimentation tanks (PST’s) also had all the mechanical rotating and fixed bridge assemblies replaced with stainless steel assemblies. All this work was carried out while the existing plant was still operational at full capacity.

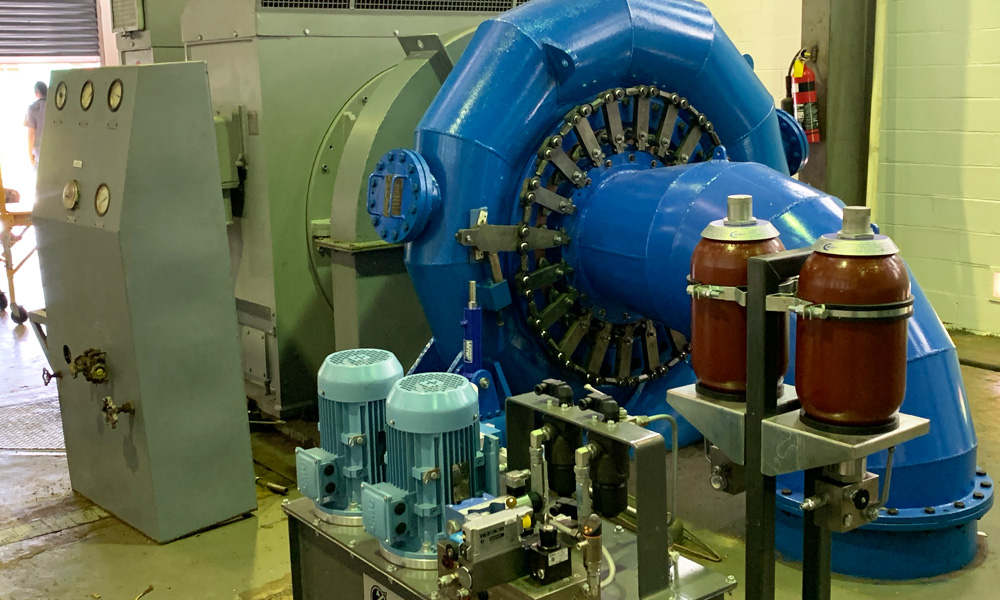

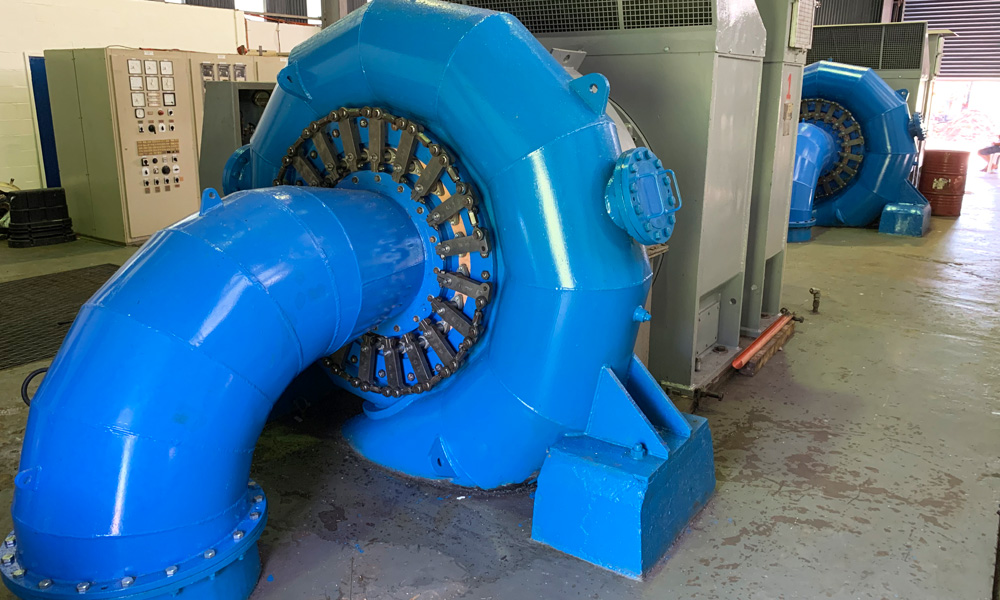

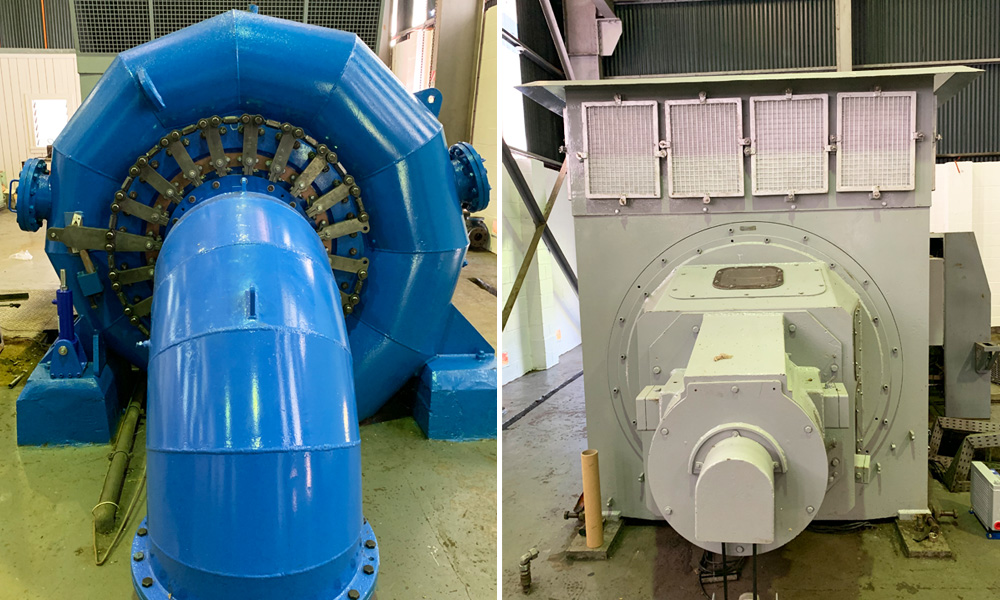

CUSTOMER - Electric Power Corporation (EPC)

LOCATION - Lalomauga, Samoa

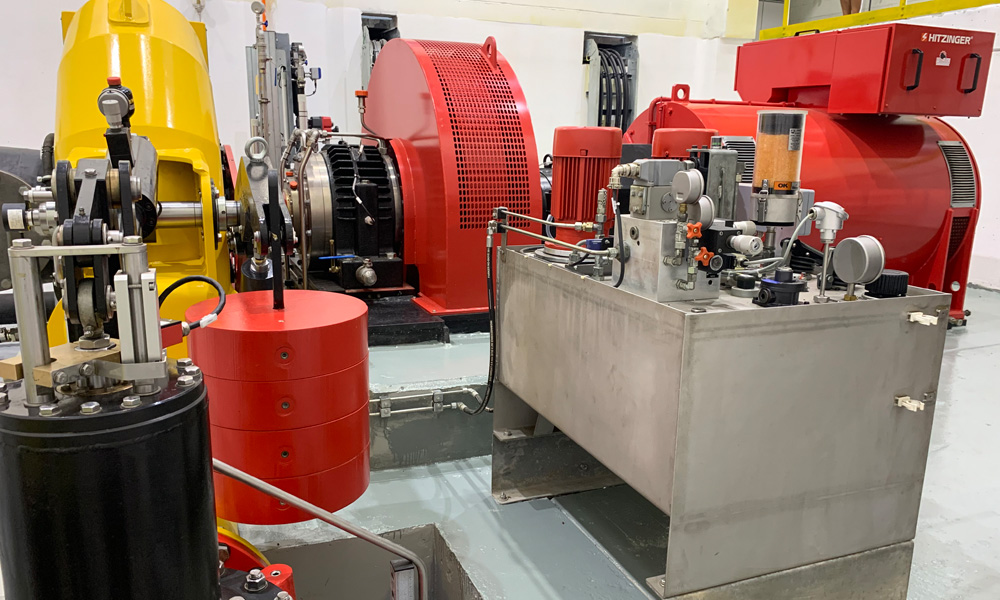

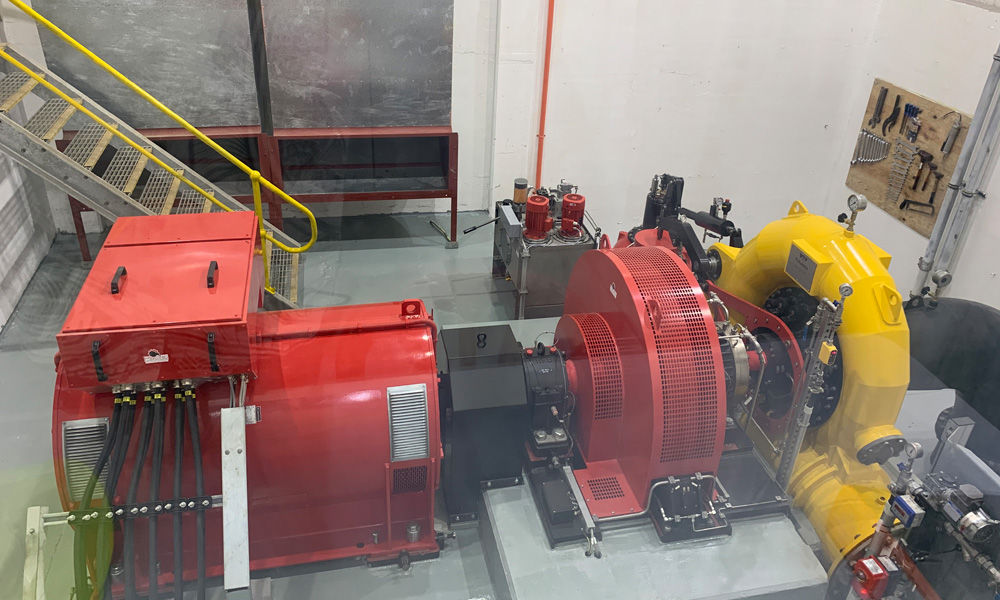

SCOPE - The project comprised design of all works and the rehabilitation of two 1.75MW hydro power units at Lalomauga Hydro Plant. The main components were dismantled and brought to New Zealand for inspection, testing, refurbishment and return to Samoa. The key works included:

We successfully completed this contract, which was delivered without any lost time accident or environmental breach. In doing so we worked in a collaborative and pragmatic manner with EPC and its other stakeholders which included a first in that due to the Covid 19 pandemic we commissioned the 2 hydro generators remotely from New Zealand. This was a first for Samoa.

CUSTOMER - Water Authority of Fiji (WAF)

LOCATION - Kinoya Suva, Fiji

SCOPE - This was a design and supply contract for the supply of aeration system for the Kinoya WWTP upgrade works. The key equipment supplied included 6 x 90kW blowers and fine bubble diffused membrane aeration systems. The blowers were set up for remote access. These blowers were eventually commissioned during the Covid 19 lockdown. Our engineers at site worked remotely with the Italian supplier to commission these machines.

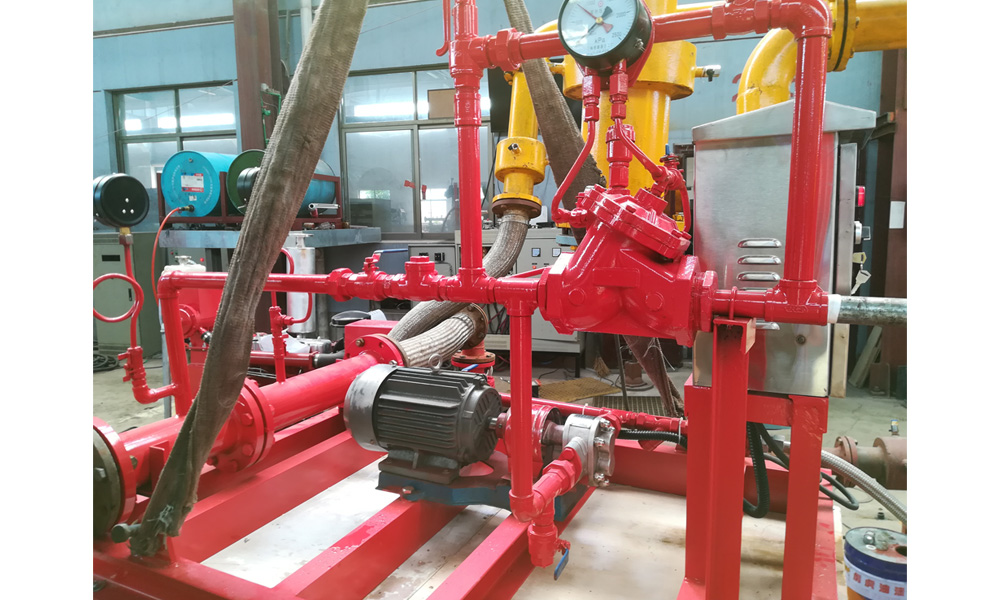

CUSTOMER - Energy Division, Ministry of Finance, Government of Samoa

LOCATION - Sogi Fuel Terminal, Apia, Samoa

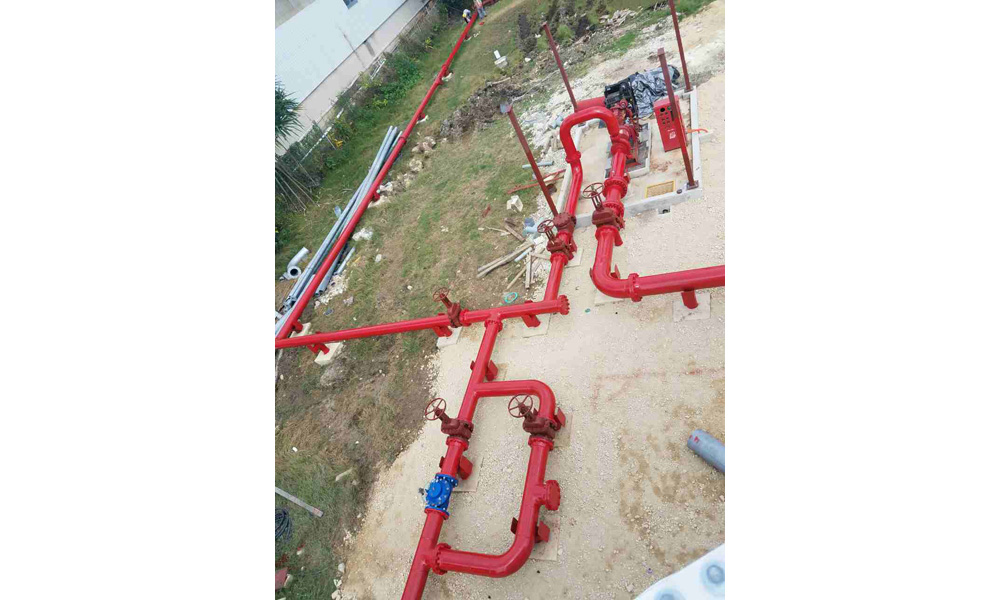

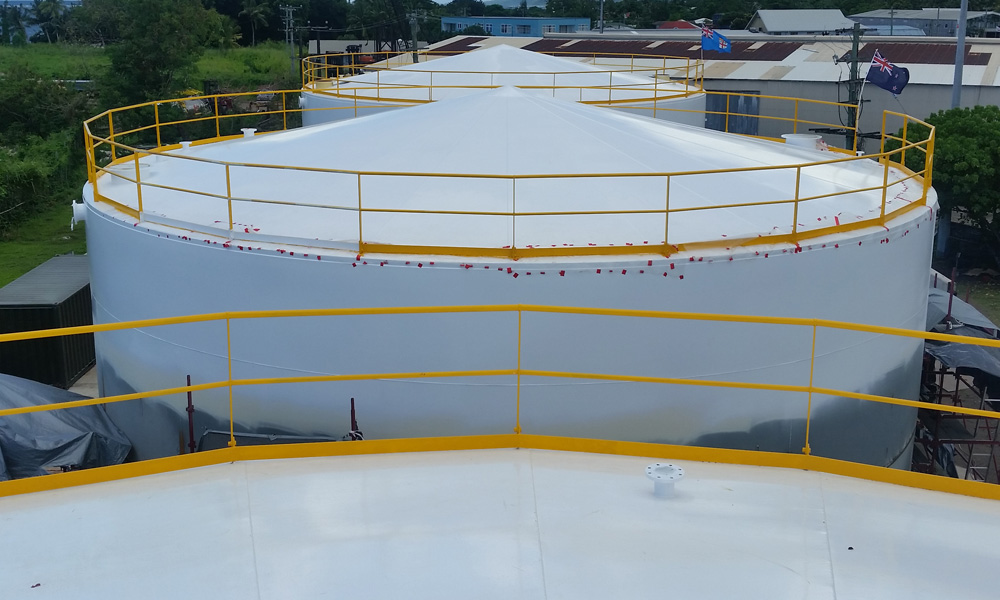

SCOPE - The work involved the design and supply of two fire water tanks each with a capacity of 125,000 litres, two diesel driven fire water pumps and a foam pump with foam proportioner. We also provided supervision of onsite installation and testing of the firewater tanks.

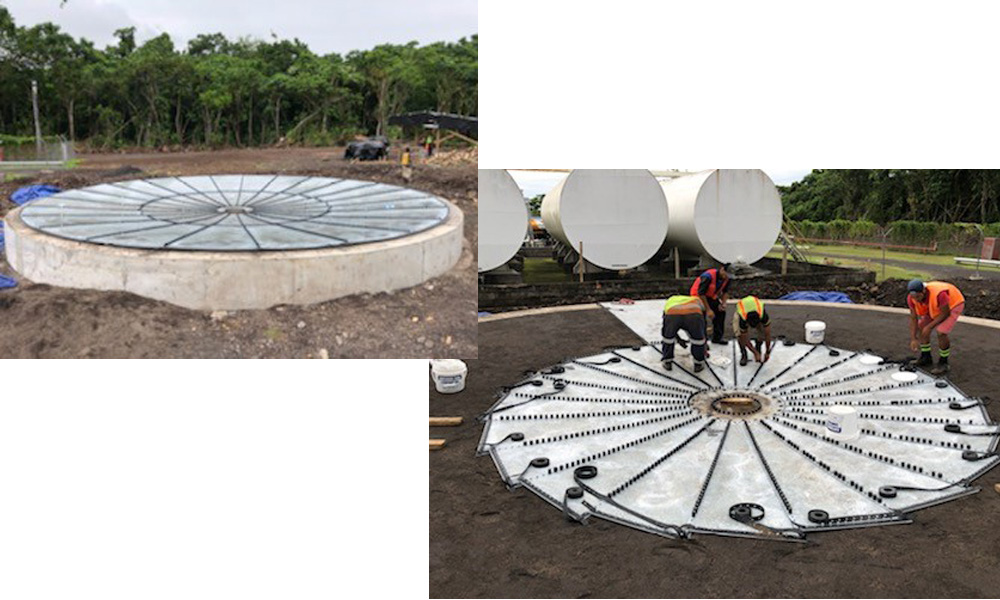

CUSTOMER - Energy Division, Ministry of Finance, Government of Samoa

LOCATION - Salelologa Fuel Terminal, Savaii, Samoa

SCOPE - The work involved the design and supply of one fire water tank each with a capacity of 700,000 litres and one 600T galvanized diesel tank. We also provided supervision of onsite installation and testing of the firewater and diesel tanks.

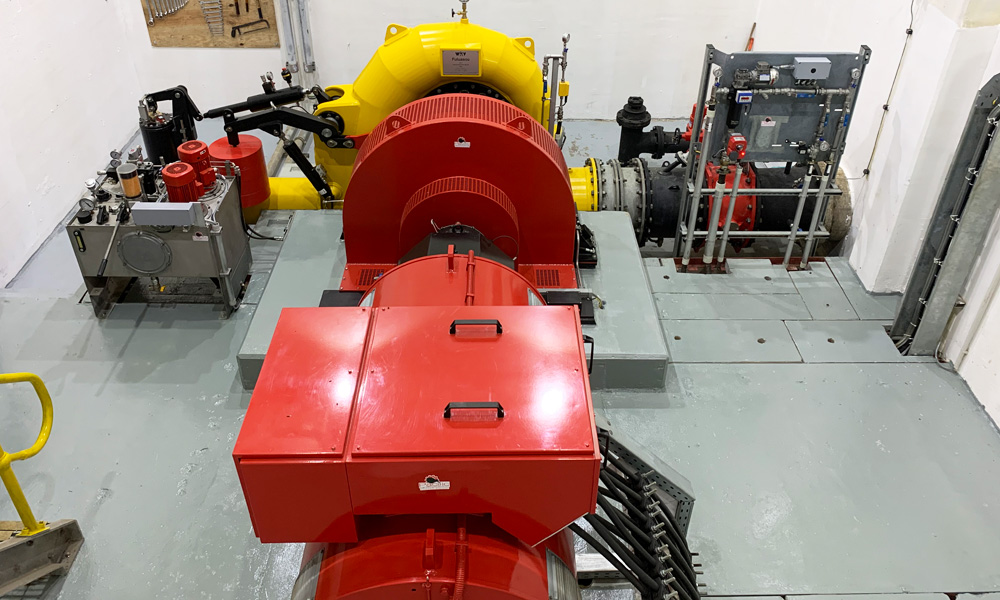

CUSTOMER - Electric Power Corporation (EPC)

LOCATION - Fuluasou, Apia, Samoa

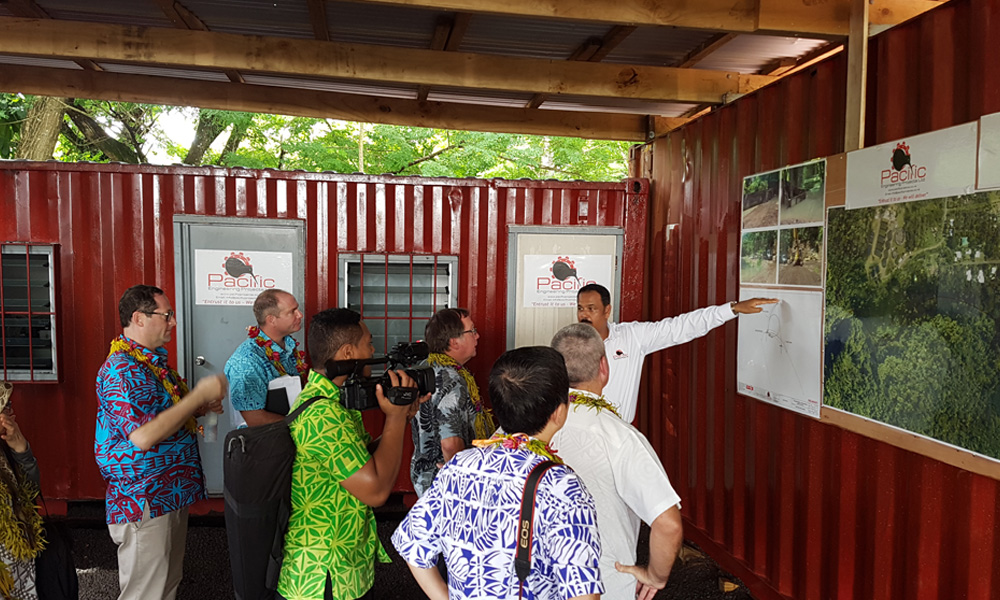

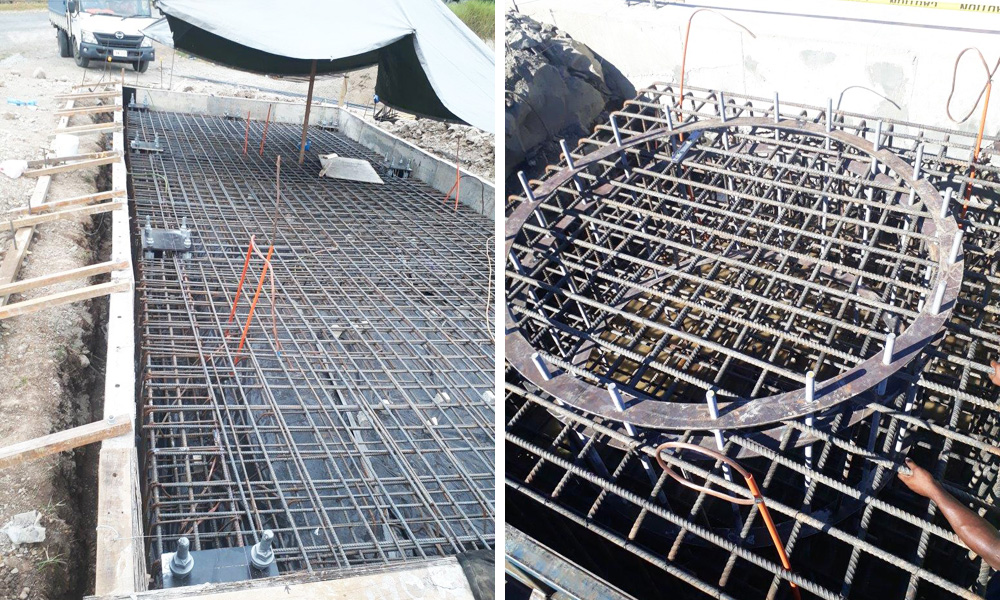

SCOPE - This project was part of EPC’s renewable energy development and power sector rehabilitation project. This was a complete design and build project where we were involved right from the groundbreaking ceremony. Our work included the following major works:

The power generated was lot more than the guaranteed power output.

CUSTOMER - Total Fiji Limited

LOCATION - Walu Bay, Suva, Fiji

SCOPE - The work was a mix of construction only for the civil works and tank concrete foundation and full design and build for the tank and protection systems.

We designed, supplied, and installed a leak detection system which included a HDPE liner below the tank.

For the tank, PEP designed the tank to API650 and TOTAL standards including independent verification by a New Zealand design verifier and independent certification by a Fiji registered structural engineer. PEP supplied the pre-fabricated tank kit set, onsite fabrication, installation, and testing of the tank. The scope also included the blasting and painting works, hydrotesting and installation of nozzles and associated piping. We also designed, installed, tested, and commissioned a cathodic protection system.

CUSTOMER - Palau Public Utilities Corporation (PPUC)

LOCATION - Koror Palau

SCOPE - We designed and built a submersible wastewater pump station. The scope for the pump station included motor control centre, automatic controls, 13.8/0.48kV step down transformer, 13.8kV HV mains cabling and termination to the national grid. The pump station included a valve chamber and a screen system to ensure large debris were collected and removed so the pumps did not get damaged.

In addition to this we supplied and installed:

CUSTOMER - Energy Fiji Limited (EFL)

LOCATION - Vuda, Lautoka, Fiji

SCOPE - Our work included the design verification and construction of the power station and the electrical switch room buildings. The work also included all the civil works to prepare the area for construction. This included a large amount of excavation and some engineered fill to get the required RL for building works to start. In addition, we installed mechanical and electrical equipment.

CUSTOMER - Water Authority of Fiji (WAF)

LOCATION - Namau, Tailevu,Fiji

SCOPE - The work included the design, supply and installation of the MV mains cables from Electricity Fiji Limited (EFL) pole to main switchboard and power to all the key electrical field devices. We also designed, supplied and installed the main switchboard. The scope also included the design, supply and installation of lighting for the complete plant. All lighting was energy saving LED lights. All the yard and street light poles used renewable materials only. PEP also designed and constructed the main switchboard building. As part of the project PEP supplied and installed solar powered yard and street lighting.

CUSTOMER - Fiji Electricity Authority (FEA)

LOCATION - Kinoya, Suva, Fiji

SCOPE - The work involved topographical survey, geotechnical investigation, design, supply and construction of the tank foundation. The scope also included the design, supply, installation and testing of a fire water tanks with a capacity of 500,000 litres.

CUSTOMER - Pacific Fishing Company (PAFCO)

LOCATION - Levuka, Ovalau, Fiji

SCOPE - The project involved the following works to construct and commission an efficient cold store for PAFCO at their Levuka facility.

CUSTOMER - Energy Division, Ministry of Finance, Government of Samoa

LOCATION - Apia Samoa

SCOPE - Our scope of work was to:

All the work was carried inside an operational fuel terminal and wharf.

CUSTOMER - Electric Power Corporation (EPC)

LOCATION - Taelefaga, Apia, Samoa

SCOPE - Our work was to design, supply, install and commission a new 0.415/6.6kV generator grid connected transformer. This new transformer was installed in place of an existing transformer. We also refurbished the existing transformer that was taken out.

CUSTOMER - Total Fiji Ltd

LOCATION - Touliki, Nuku’alofa, Tonga

SCOPE - The scope of work was to install and commission a fire water system at the Touliki Terminal in Nuku’alofa. This included

CUSTOMER - Starkist Samoa Company

LOCATION - Pago Pago, American Samoa

SCOPE - The scope included the following main components:

The work was carried out on a 24 x 7 basis and the shutdown was complete weeks ahead of the schedule.

CUSTOMER - Momi Bay Resort Limited

LOCATION - Momi Bay, Nadi Fiji

SCOPE - The scope was a turnkey design, build and commission a wastewater treatment plant using SBR technology.

The scope included all process design and P and ID’s and complete engineering of all civil, building, structural, mechanical, electrical and controls using PLC. The key components included:

CUSTOMER - Water Authority of Fiji

LOCATION - Rara, Labasa, Fiji

SCOPE - The project was the supply of all materials and the construction of 1,000,000 litre potable water reinforced concrete reservoir with roof. The work also included the construction of chip sealed access roads.

In addition we carried out all the bulk excavation, supply and construction of concrete chambers.

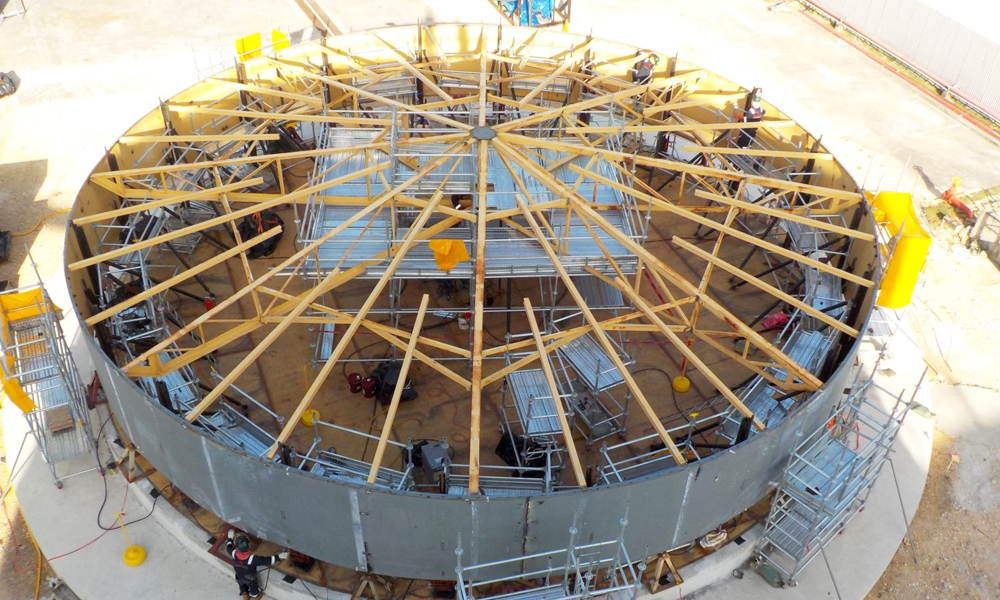

CUSTOMER - Ministry of Finance, Energy Division, Government of Samoa

LOCATION - Apia Samoa

SCOPE - The scope was to supply, fabricate, install, test and calibrate 3 off 3,000,000 litre diesel fuel tanks at the Apia wharf terminal. The tanks were constructed using the jacking method – a first for Samoa.

We also supplied, fabricated and installed all the fuel piping within the terminal.

CUSTOMER - American Samoa Power Authority (ASPA)

LOCATION - Satala, Pago Pago, American Samoa

SCOPE - Our scope was to design, build and commission the 38/15kV Satala Substation and supply the transformers for the Tafuna 38/15kV substation. The work included:

CUSTOMER - Water Authority of Fiji (WAF)

LOCATION - Tovata, Suva, Fiji

SCOPE - Our scope of work was to design, supply, install and commission a booster pump at the Tovata pump station. The key elements included:

CUSTOMER - Water Authority of Fiji (WAF)

LOCATION - Matavo, Sigatoka and Waiwai, Ba in Fiji

SCOPE - Construction of a wet well water pump station and supply and laying of 4kM gravity mains.

For Matavo intake pump station in Sigatoka the work included:

For Waiwai gravity mains in Ba, the work included:

CUSTOMER - Solomon Islands Electricity Authority

LOCATION - Honiara, Solomon Island

SCOPE - The scope of work included:

All this work was undertaken along the main Kukum highway.

CUSTOMER - Samoa Water Authority

LOCATION - Alaoa, Malololelei and Fuluasou, Samoa

SCOPE - The work included the construction of three new water treatment plant disinfection systems at Alaoa, Malololelei and Fuluasou Urban water treatment plants and the refurbishment and upgrade of the Fuluasou EU rural plant. The main elements of the works included:

CUSTOMER - Trimarine, Inc & Samoa Tuna Processors, Inc. (STP)

LOCATION - Pago Pago, American Samoa

SCOPE - This was a design and build project for Trimarine, Inc. subsidiary Samoa Tuna Processors, Inc.

The project involved the following works to construct and commission an efficient cold store for STP at their Pago Pago facility.

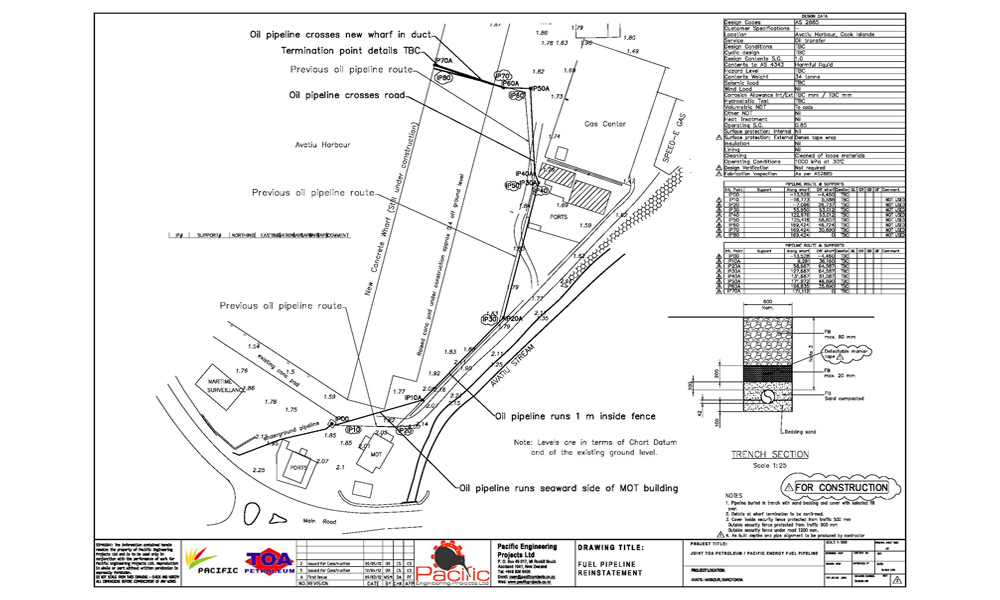

CUSTOMER - Toa Petroleum

LOCATION - Rarotonga, Cook Islands

SCOPE - Our scope was to provide the design associated with the relocation of the fuel terminal in Rarotonga. The work also included the design of the fuel pipeline from the wharf to the terminal (shared with Pacific Energy)

In addition to this we provided project budgeting services, project management and contract administration.

CUSTOMER - New Zealand Ministry of Foreign Affairs (MFAT)

LOCATION - Labasa Fiji

SCOPE - Design, supply and installation of potable water tank, booster pump and controls for automated filling of header tank. Supply and installation of a new ring mains for potable water supply to the hospital.